Read the information listed below to determine which type of cylinder you require.

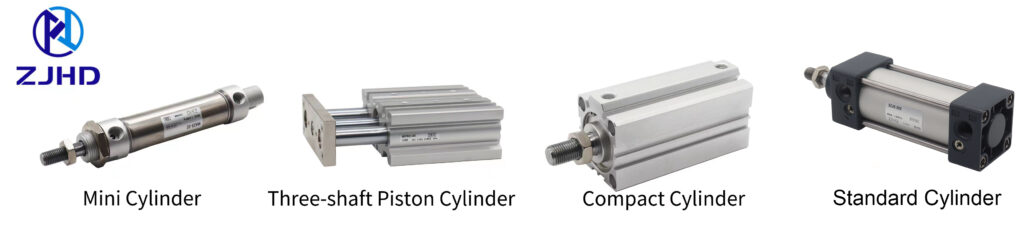

1, Cylinder Series

according to the purpose of use, cylinder diameter and range of travel, select the appropriate cylinder series.

2, Cylinder Bore Size

according to the load, speed and operating pressure to determine the cylinder diameter, one of the important selection steps are as follows:

a. determine the load weight

(including workpiece, fixture, guide rod and other movable parts of the weight) ;

b. select the use of air pressure (supply cylinder compressed air pressure) ;

c. determine the direction of cylinder action.

3, select the cylinder stroke:

the cylinder stroke relates to working environment and institutions. You need to leave an appropriate margin in stroke, for easy installation and debugging Volume. Standard stroke should be in priority consideration, for fast delivery and reduce costs.

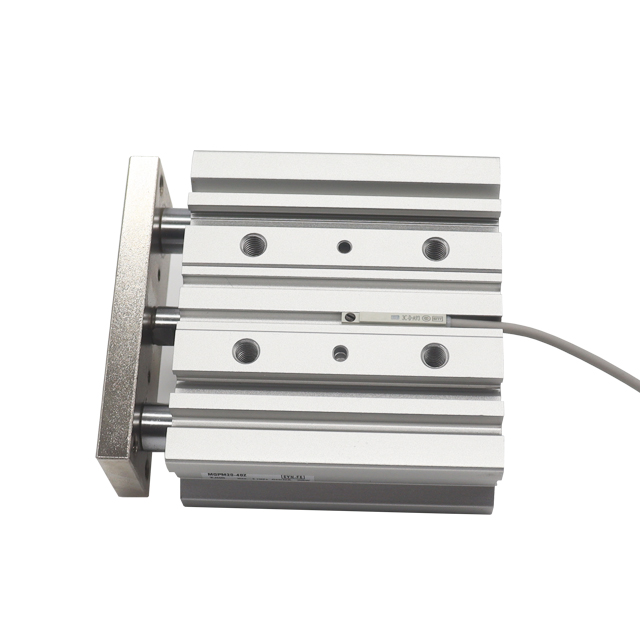

4, The choice of installation way:

decided by the installation location, use purposes and other factors. Generally choose the fixed type cylinder.

5. Choose the buffer type:

depending on the speed of the piston to decide whether to use the buffer device.

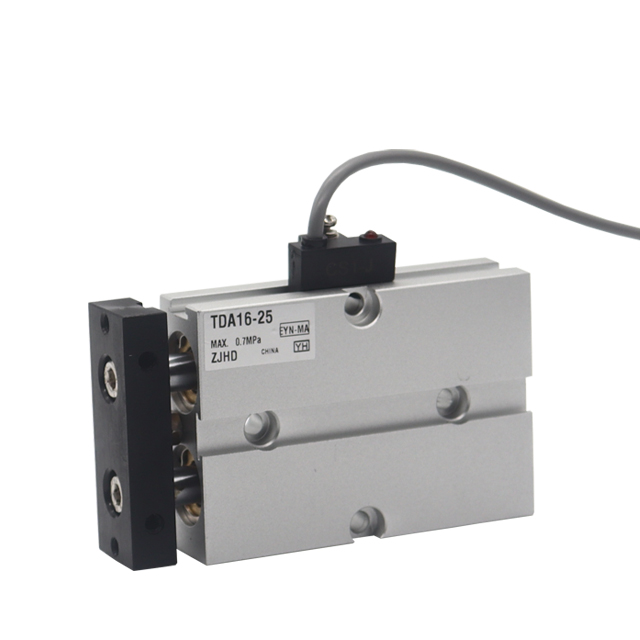

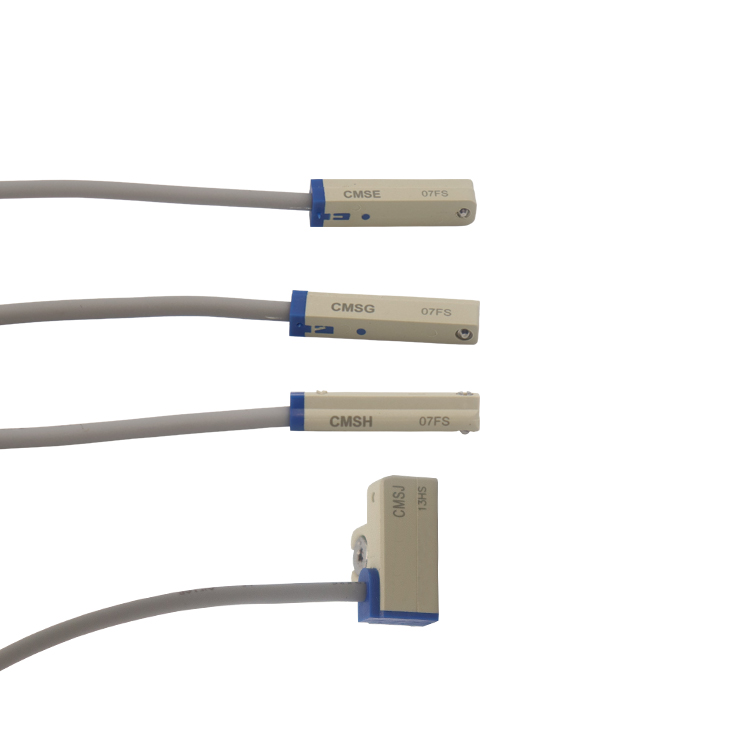

6. Decide whether the cylinder need equip magnet:

when the pneumatic system is electrically controlled, the cylinder with magnetic switch can be selected.

7. Select accessories:

such as solenoid valves, throttle valves, couplings and even pipes, which may seem insignificant but affect performance.

Of course, once the problem of aerodynamic selection is solved, others can basically be matched according to demand.